The Enduring Legacy of our Smith & Wellstood Cooker

In 2006, the acquisition of our new home was serendipitously accompanied by an unexpected treasure: a Smith & Wellstood Cooker. This magnificent 305 kg cast-iron stove, capable of burning either wood or coal, captivated us instantly. Our enthusiasm was so profound that we immediately pressed the estate agent for confirmation of its inclusion in the sale. Her affirmative response was met with unbridled delight, solidifying our decision to purchase the property.

Once the keys were in hand and the house officially ours, our intrigue surrounding the cooker deepened. We embarked on an investigation into its origins and, to our astonishment, uncovered its considerable historical and monetary value. This revelation transformed our appreciation for the appliance from mere affection to a deep respect for its craftsmanship and heritage.

Preparations and discussions are under way for the meticulous removal and transportation of the stove to Cape Town. There, it will undergo a comprehensive overhaul by specialists, ensuring its complete restoration to its original grandeur and full functionality. Upon its return, this cherished Smith & Wellstood Cooker will once again take pride of place in our home, ready to continue its legacy for generations to come.

Smith and Wellstood commenced operations of their foundry in 1873. The company's incorporation occurred in 1887, documented with registration number SC001688. A significant expansion took place in 1890 through the amalgamation with George Ure & Co, which also included the acquisition of Columbian Stove Works. The business experienced a change of ownership in 1947, subsequent to the demise of its then-managing director, George Ure. Smith and Wellstood is recognized as a highly esteemed and historically significant foundry within Bonnybridge, Scotland.

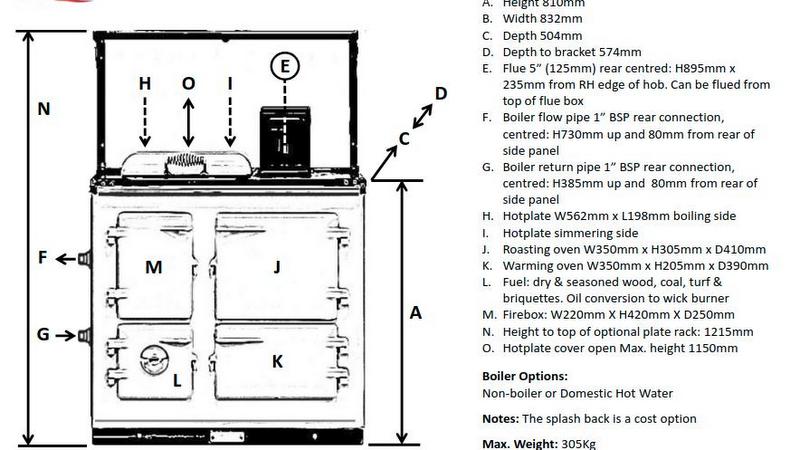

Product Overview: The Wellstood Cooker

Smith & Wellstood has a distinguished history of producing range cookers in Scotland, with the two-oven model being particularly well-received in Ireland. This Wellstood model is equipped with an elongated hotplate to facilitate the simultaneous heating of multiple cooking vessels. Airflow control is managed by a rotary damper integrated into the ash box door. Consumers can select between two versions of the cooker: one inclusive of a water boiler and one without.

Maintenance is simplified through accessible design; the hotplate can be easily lifted, and the flue box door removed for cleaning purposes. The two-oven Wellstood is customizable and available in our full range of standard colours. Clients have the option to enhance their cooker with a plate rack and splash back panel, or an ornamental water tank designed to be situated on the left side of the primary unit.

Distribution of the cooker in South Africa was managed by Geo. Findlay Co. Ltd, Cape Town, and W.B. Cameron, Durban. These entities operated under a licensing agreement with the Smith & Wellstood Foundry, head quartered in Bonnybridge, Scotland.

Company Timeline

1870: Ure & Co., a partnership comprising Ure, Smith, and Wellstood, established a new foundry opposite their existing Columbian Stove Works. A mutual agreement stipulated that the new Bonnybridge Foundry would be owned and operated by George Ure and his family, focusing on the production of sewing machines and general castings. Concurrently, the Columbian Stove Works, under the continued ownership of the Ure & Co. partners, would specialize in stoves and ranges. Early products from the Bonnybridge Foundry included water tubes for boilers, tea drying stoves, and machinery for Messrs. Davidson of Belfast. The sewing machine contract was substantial, with production reaching up to 6,000 bodies per week by 1882, including japanning services.

1873: Smith & Wellstood acquired the Columbian Stove Works, resulting in George Ure retaining sole ownership of the Bonnybridge Foundry. The firm was subsequently renamed George Ure & Co. George Ure's son, George, his son-in-law, Allan Gillespie, and associates James Mochrie and William Mitchell, assumed management responsibilities for the newly structured firm.

1879: The company's workforce reached 400 employees.

1883: A Turnbull's patent equilibrium safety valve was installed on the works' boiler, a measure taken in response to boiler explosions at other local foundries.

1884: The Singer Manufacturing Co. constructed its own factory at Kilbowie on the Clyde, transferring sewing machine production to their new facility.

December 1884: George Ure & Co. was incorporated as a limited company with a capital of £60,000, divided into 3,000 shares of £20 each. Of these, 2,995 shares were issued as paid up to the extent of £17 per share. The works and stock were valued at a purchase price of £51,000. Share allocations included George Ure (408 shares), George Reid Ure (1,137 shares), John Reid Ure (775 shares), Allan Gillespie (465 shares), James Mochrie (105 shares), and William Mitchell (105 shares). Anne Steel, wife of the minister, acquired 5 shares.

1885: George Ure transferred management of the Bonnybridge Foundry to his sons and son-in-law. To offset the loss of the Singer contract, the production range was expanded to include piano frames, baths, grates, and ornamental goods. However, a subsequent blow came when another significant customer, Davidson of Belfast, also established its own foundry. This led to a rapid decrease in production at the Bonnybridge Foundry, with a portion of the facility temporarily becoming disused.

1890: Due to declining business, George Ure & Co. amalgamated with Smith & Wellstood. This decision was largely a formality, given the intermarriage between the Ure and Smith families. The unified entity adopted the name Smith & Wellstood.